A Guide to Stainless Steel Bar Gratings

Introduction

This guide explains stainless steel bar gratings’ uses benefits and applications across industrial and municipal projects in Canada.

In demanding industrial and public environments, material selection plays a critical role in safety, longevity, and performance. Stainless steel bar gratings are widely used across Canada for projects where corrosion resistance, heat tolerance, and durability are essential. From food processing facilities to wastewater plants and transit infrastructure, these gratings are designed to perform where other materials may fall short.

This guide is intended for facility managers, engineers, contractors, architects, and municipal decision makers who need a deeper understanding of how stainless steel bar gratings are used across industrial, institutional, and infrastructure projects.

It explains where stainless steel excels, how different configurations perform, and why it is often selected for long term reliability in challenging conditions.

In this guide, we will cover

Table of Contents

The Challenge of Harsh Industrial Environments in Canada

Industrial and municipal facilities in Canada face a unique combination of environmental and operational challenges. Exposure to moisture, chemicals, temperature extremes, and continuous use can significantly shorten the lifespan of many materials. Flooring and access systems must remain safe and structurally sound even when subjected to corrosive agents, steam, washdowns, or outdoor weather conditions.

Carbon steel gratings, while strong, may require additional protection in corrosive environments. Aluminium offers lightweight benefits but may not always meet strength or temperature requirements. In applications where sanitation, corrosion resistance, and durability are critical, these limitations create risk over time.

Facility managers and engineers must also consider safety and maintenance. Slippery surfaces, material degradation, and frequent replacement can lead to downtime and higher long-term costs. For public infrastructure and regulated environments, reliability is not optional.

This is where stainless steel becomes a practical solution. Its inherent resistance to corrosion, ability to withstand high temperatures, and long service life make it well suited for some of the most demanding environments across Canada.

Why Stainless Steel Is Chosen for Industrial Grating Applications

Stainless steel offers a unique combination of properties that make it suitable for grating systems in challenging conditions. Unlike coated materials that rely on surface protection, stainless steel resists corrosion through its alloy composition. This allows it to perform consistently even when exposed to moisture, chemicals, or frequent cleaning.

Key performance advantages include:

- Resistance to rust and corrosion in wet or chemical environments

- Stability under high temperatures and thermal cycling

- Strength suitable for industrial loads and traffic

- Long service life with minimal maintenance

- Cleanable surfaces for hygienic environments

Because of these properties, stainless steel grating is often specified for facilities where failure or degradation could compromise safety, compliance, or operations.

Stainless Steel Bar Grating Configurations

Stainless steel bar gratings are available in several construction styles, each suited to different performance and design needs. Borden produces a complete line of stainless steel gratings manufactured in Canada, allowing projects to be matched with the appropriate configuration.

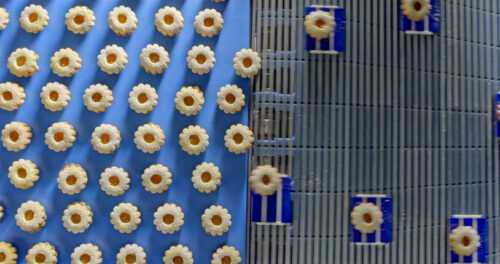

Pressure Locked Stainless Steel Gratings

Pressure locked gratings are produced by pressing cross bars into pre punched bearing bars under high pressure. This creates a tight mechanical connection and a smooth, uniform appearance. In stainless steel, this style is commonly used where aesthetics, precision, and durability are equally important.

Typical applications include public walkways, architectural features, and service platforms where visual consistency and corrosion resistance are required.

Heavy Duty Stainless Steel Gratings

Heavy duty stainless steel gratings are designed for environments with higher load requirements. These gratings use deeper bearing bars and robust construction to support equipment, vehicles, or concentrated loads. Stainless steel allows these systems to maintain strength even in corrosive or high heat conditions.

They are commonly used in industrial processing plants, energy facilities, and infrastructure projects where both strength and environmental resistance are critical.

Riveted Stainless Steel Gratings

Riveted construction remains one of the strongest grating options available. In stainless steel, riveted gratings offer exceptional fatigue resistance and durability. The riveted connections allow the grating to absorb vibration and repeated stress without loosening or deforming.

These gratings are often specified for bridges, transit platforms, and industrial areas subject to constant movement or heavy traffic.

Where Stainless Steel Bar Gratings Are Used in Canada

Across Canada, stainless steel bar gratings are used in a wide range of industrial, municipal, and institutional applications. Their versatility allows them to perform reliably in both indoor and outdoor environments.

Industrial and Processing Facilities

In food processing, pharmaceutical, and chemical plants, sanitation and corrosion resistance are top priorities. Stainless steel gratings withstand frequent washdowns and exposure to cleaning agents while maintaining structural integrity.

Municipal and Infrastructure Projects

Wastewater treatment plants, pumping stations, and water management facilities rely on materials that can handle moisture and chemicals over long periods. Stainless steel gratings are commonly used for walkways, access platforms, and trench covers in these environments.

Energy and Heavy Industry

Energy production and heavy industrial facilities require grating systems that tolerate heat, vibration, and harsh conditions. Stainless steel provides reliability where temperature fluctuations and corrosive elements are present.

Commercial and Institutional Facilities

Hospitals, laboratories, and institutional buildings often specify stainless steel for its clean appearance and durability. Gratings are used in service areas, mechanical rooms, and access platforms where safety and cleanliness matter.

Where Stainless Steel Outperforms Other Grating Materials

Material selection is always application specific, but there are clear scenarios where stainless steel provides advantages over other options.

Compared to carbon steel, stainless steel does not rely on coatings to resist corrosion. This reduces maintenance needs and extends service life in wet or chemical environments. Compared to aluminium, stainless steel offers greater strength and heat resistance, making it suitable for more demanding industrial loads.

In applications where long-term performance, safety, and reduced maintenance are priorities, stainless steel grating often provides the most reliable solution.

Design and Specification Considerations

When specifying stainless steel bar gratings, several factors should be considered to ensure optimal performance.

- Load requirements and traffic type

- Environmental exposure including moisture, chemicals, or heat

- Slip resistance and safety needs

- Bar spacing and ventilation requirements

- Integration with surrounding structures

Working with an experienced manufacturer ensures these factors are addressed during design and fabrication.

Quick FAQ

What environments are best suited for stainless steel bar gratings?

They are ideal for corrosive, wet, high heat, or hygienic environments such as food processing plants and wastewater facilities.

Are stainless steel gratings suitable for outdoor use in Canada?

Yes. They perform well outdoors due to their resistance to corrosion and temperature changes.

Can stainless steel gratings support heavy loads?

Yes. Heavy duty and riveted configurations are designed for industrial and infrastructure loads.

Do stainless steel gratings require special maintenance?

They typically require minimal maintenance beyond routine cleaning.

Are stainless steel gratings customizable?

Yes. They can be produced in various sizes, configurations, and finishes to meet project requirements.

Since 1955, Borden Metal Products (Canada) Ltd. has been a trusted name in bar-on-edge gratings. Based in Beeton, Ontario, we produce a complete line of riveted, welded, pressure locked, and squeeze locked bar gratings in carbon steel, aluminum, and stainless steel.

Our team has built a reputation synonymous with quality and dependability across Canada. If you’re planning a project that requires durable, safe, and long-lasting gratings, we can help.

Contact us today to book a consultation with our experts and explore the right bar grating solution for your needs.