Heavy-Duty Steel Bar Grating – The Complete Guide

Introduction

From industrial plants to municipal infrastructure projects, heavy-duty steel bar grating remains one of the best choices for building strong, safe, and lasting surfaces.

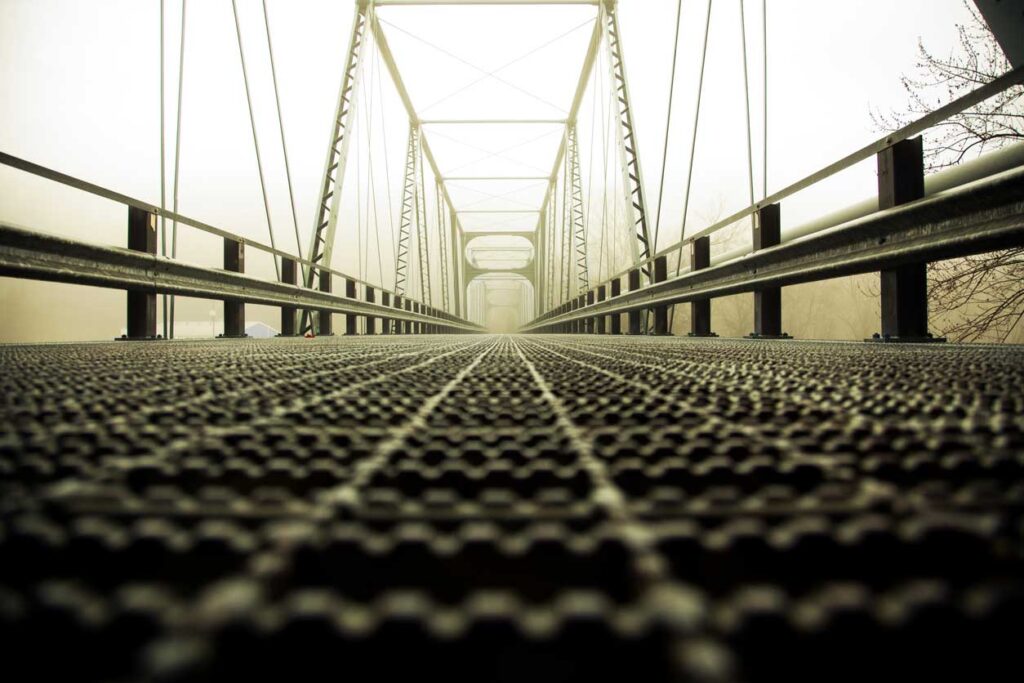

Whether it is supporting forklift traffic inside a warehouse, forming drainage grates on public roadways, or reinforcing bridge decks under heavy loads, heavy-duty grating plays a major role in keeping workplaces and communities functional.

More than just a metal panel, steel bar grating is an engineered system designed to handle demanding conditions. It balances strength, durability, slip resistance, and load distribution, all while staying lightweight enough for efficient installation and maintenance. In industries where structural failure is not an option, choosing the right grating can greatly improve safety and performance.

Table of Contents

What Heavy-Duty Steel Bar Grating Is and How It Works

Heavy-duty steel bar grating is one of the most trusted surface materials used across Ontario’s industrial and infrastructure sectors. Built to handle higher loads and longer spans than standard grating, it is engineered for demanding environments where strength, safety, and durability are essential.

At its core, steel bar grating is a grid made from straight bearing bars running in one direction and cross bars running perpendicular to them. Together, they create a rigid panel that carries weight, allows drainage, and maintains traction. In heavy-duty applications, the bearing bars are deeper, thicker, and often spaced wider apart to support larger loads such as forklifts, heavy equipment, transport trucks, or industrial machinery.

Because of its open construction, grating offers benefits that solid surfaces cannot match. Liquids, debris, and snow can pass through, reducing slipping hazards and preventing water accumulation. The open area also reduces the overall weight of the surface, making installation and maintenance easier.

The Challenges Heavy-Duty Grating Solves in Industrial and Infrastructure Settings

Many industrial and municipal environments face recurring issues: heavy traffic, standing water, uneven flooring, and premature wear caused by equipment use. Heavy-duty grating addresses these concerns by offering a strong, stable, and low-maintenance surface.

Handling Heavy Loads

Solid flooring can warp, crack, or deform under high pressure. When heavy trucks or forklifts move across a surface repeatedly, the stress builds up. Heavy-duty grating distributes these forces efficiently, reducing stress at any one point and helping prevent failure. This is especially important in busy warehouses, public loading areas, and municipal facilities.

Managing Water, Snow, and Debris

Ontario experiences significant seasonal changes, including rain, snow, ice, and freeze-thaw cycles. These conditions cause water to pool on solid surfaces, increasing slip risks and accelerating corrosion. Heavy-duty steel bar grating solves this by allowing water and snow to fall through its open structure. This reduces freeze buildup, improves traction, and helps keep walkways safe during winter.

Ensuring Traction and Safety

Anti-slip surfaces are essential in industrial and public environments. Many heavy-duty gratings are available with serrated bearing bars that provide improved traction, especially when surfaces may be oily, wet, or icy. This enhances worker safety and reduces the likelihood of slips and falls.

Preventing Premature Wear

Facilities that depend on solid plates or concrete pads may struggle with early deterioration. Heavy-duty bar grating resists wear caused by vibration, machinery traffic, and chemical exposure. It can also be replaced in sections, which makes repairs more manageable without requiring a full floor replacement.

Supporting Drainage and Ventilation

In municipal infrastructure, airfields, transit systems, and wastewater facilities, drainage and ventilation play key roles in maintaining performance. Heavy-duty grating can be used for trench drains, culverts, and catch basins, where it allows water and air to move freely while still supporting traffic loads.

By solving these challenges, heavy-duty steel bar grating has become a dependable choice for many different environments across southern Ontario.

Across Ontario, engineers and facility managers rely on steel bar grating in places where safety and long-term performance matter. From bridge decks and loading docks to airport culverts and warehouse floors, it is a durable material built to last.

How Heavy-Duty Grating Is Designed for Strength, Safety, and Load Capacity

The strength of heavy-duty bar grating comes from a combination of bar size, spacing, material choice, and fabrication method. Engineers evaluate these factors to ensure the grating can support the intended load with minimal deflection.

Bearing Bars and Load Transfer

The bearing bars support the majority of the load. They can be flat bars, I-bars, or square bars, depending on the required performance. Heavier loads demand deeper and thicker bearing bars. Their spacing plays a role in both weight and strength, with closer spacing increasing load capacity.

The open design would not work without cross bars, which tie the bearing bars together. They help distribute weight evenly across the panel, reducing localized stress.

Fabrication Methods

Heavy-duty grating is made using several different methods:

- Welded grating joins bearing bars and cross bars through electric resistance welding. This creates a strong, single-piece unit that performs well in industrial settings.

- Pressure-locked grating uses mechanical pressure to fuse bars together, creating a clean and uniform appearance for architectural or public-facing uses.

- Riveted grating is known for its fatigue resistance and stability under vibration. It is often used in bridges, public walkways, and transportation infrastructure.

Each fabrication method offers advantages based on the application’s performance needs.

Load Ratings and Standards

In North America, heavy-duty bar grating design commonly follows ANSI/NAAMM MBG 531 for determining load capacity and deflection. In Canada, heavy-duty grating used in bridge or roadway applications must align with the principles of CSA S6, the Canadian Highway Bridge Design Code. These standards ensure that engineers use consistent methods for calculating loads, spans, and material performance.

Deflection and Comfort

Grating must remain stable and comfortable to walk or drive across. Deflection limits help achieve this. Engineers calculate deflection based on span and load, making sure that the grating does not bend excessively. Less deflection means smoother operation for vehicles and safer footing for pedestrians.

Safety and Slip Resistance

The design of a grating surface directly affects safety. Serrated bars increase friction, making them a better choice for wet or oily environments. Smooth bars may be used in dry, indoor settings where comfort or aesthetics matter more.

Together, these design elements ensure that heavy-duty grating performs reliably under real-world conditions.

READ MORE > How Heavy Duty Steel Grating Provides Essential Safety Across Canadian Industries

Types of Heavy-Duty Steel Bar Grating and When to Use Each One

Heavy-duty grating is available in several styles, each designed to balance strength, weight, drainage, and safety. Choosing the right type depends on the conditions of the site and the loads it must support.

Welded Heavy-Duty Grating

Welded grating is the most common type used in industrial environments. It offers strong connections between bars, making it reliable and durable. It is ideal for:

- Forklift aisles

- Mezzanines

- Service platforms

- Equipment rooms

The welded construction provides excellent load distribution and is suitable for places where vibration or constant movement is common.

Riveted Heavy-Duty Grating

Riveted grating features mechanical joints created through steel rivets. This method produces a truss-like structure that excels in fatigue resistance. It is often used in:

- Bridge decks

- Transit systems

- Public walkways

- Infrastructure applications needing long-term stability

It handles repeated stress well, making it a strong choice for places with constant traffic.

Pressure-Locked Grating

Pressure-locked grating is created through mechanical pressure that locks bearing bars and cross bars together. It has a more uniform appearance and is often used where visual appeal is important, as well as in:

- Architectural designs

- Public facilities

- High-visibility walkways

While it is strong and durable, it is used more in light-to-medium heavy-duty environments.

I-Bar and Rectangular Bar Designs

Some heavy-duty gratings use I-shaped bars to reduce weight without sacrificing strength. These are ideal for large spans or places where weight reduction is needed. Rectangular bars are more traditional and sturdy, used for maximum load capacity.

Each type of grating has strengths that make it ideal for different conditions. Understanding these helps engineers and facility managers choose the right option for long-term performance.

Engineering Considerations for Load, Span, Deflection, and Safety

Designing with heavy-duty grating involves more than choosing a bar size. Engineers must evaluate load type, span length, deflection limits, and environmental conditions to ensure safe performance.

Load Types

Industrial environments experience many different loads:

- Static loads, such as equipment resting on the grating

- Rolling loads, such as forklifts or pallet jacks

- Impact loads, caused by materials being dropped

- Vehicular loads, including trucks and maintenance vehicles

Each load type must be considered when selecting the grating.

Span and Support Spacing

The distance between supports influences how much the grating will flex under weight. Shorter spans mean higher load capacity. Engineers use load tables to match grating profiles to span requirements, ensuring safe performance.

Deflection Control

Deflection affects safety, comfort, and wear. For example, forklift operators benefit from stable surfaces, while pedestrians need reliable footing. Following industry guidelines helps maintain acceptable deflection limits.

Environmental Factors

Ontario’s climate can introduce moisture, ice, and temperature swings. Grating must be designed to handle:

- Corrosion from road salt

- Freeze-thaw cycles

- Snow and debris buildup

- Outdoor exposure

Choosing the right material and surface finish is essential for long service life.

Compliance with Canadian Practices

While Ontario does not have its own bar grating code, engineers must still meet Canadian design expectations. Heavy-duty bar grating used in infrastructure must align with the principles set out in:

- CSA S6 for bridge and vehicular load considerations

- ASTM and CSA steel standards for material properties

- ANSI/NAAMM MBG 531 for grating span and load design

This ensures grating installations meet the safety, strength, and performance needs for Canadian projects.

Common Applications Across Industrial, Commercial, and Municipal Sectors

Heavy-duty grating is used in many environments due to its strength, versatility, and drainage capabilities. Across southern Ontario, it is commonly found in:

Industrial Facilities

- Forklift aisles

- Mezzanines and maintenance platforms

- Equipment rooms

- Oil and chemical handling areas

- Conveyor access paths

Municipal Infrastructure

- Roadway drainage grates

- Catch basins and trench drains

- Public transportation platforms

- Bridge decks and pedestrian walkways

Commercial and Institutional Environments

- Parking structures

- Emergency access routes

- Rooftop mechanical areas

- Utility service platforms

Airfields and Transportation Systems

- Airfield drainage systems

- Service roads

- Utility trenches

- Maintenance platforms

Heavy-duty grating is chosen because it withstands years of use while maintaining safety and structural integrity.

Material Choices, Surface Options, and Corrosion Protection

Choosing the right material helps ensure long-term performance and reduced maintenance.

Carbon Steel

Carbon steel is the most common material for heavy-duty grating. It offers excellent strength and is suitable for heavy traffic. It can be galvanized for corrosion protection, especially for outdoor or humid environments.

Stainless Steel

Stainless steel is ideal where corrosion resistance is essential. It is commonly used near water, in food-processing environments, and in chemical facilities.

Aluminum

Aluminum is lightweight and resistant to corrosion. It is easier to handle and install, making it suitable for areas where weight matters.

Surface Types

Grating surfaces play a role in safety:

- Smooth surface for indoor or low-slip environments

- Serrated surface for superior traction where water, oil, or ice may be present

Protective Coatings

Hot-dip galvanizing is the most common protective finish. It provides long-term corrosion resistance and improves durability in outdoor applications. Powder coating or paint may be used for additional protection or to match aesthetic requirements.

Selecting the proper combination of material and finish ensures the grating performs well in its intended environment.

Quick FAQ

What is heavy-duty steel bar grating used for

It is used for forklift aisles, industrial floors, bridge decks, drainage systems, airfields, and other areas needing high load capacity.

How strong is heavy-duty grating

Its strength depends on bar size, span, material, and type of load. Engineers use NAAMM load tables to determine safe spans.

Is steel bar grating safe in winter

Yes. Its open design allows snow and water to fall through, reducing slipping risks and preventing ice buildup.

Can heavy-duty grating be galvanized

Yes. Hot-dip galvanizing provides long-term corrosion resistance and is recommended for outdoor use.

Does Borden offer custom fabrication

Yes. Borden manufactures panels to meet project-specific spans, loads, and dimensions.

Heavy-duty steel bar grating is essential for creating strong, safe, and reliable surfaces across Ontario’s industrial and municipal sectors. Whether you are designing a new facility or upgrading existing infrastructure, Borden Gratings can help you choose the right product for your project.

Contact us today to book a consultation with our experts and explore the right bar grating solution for your needs.