Our Products

Roadway Gratings

Pressure Locked Gratings

Sidewalk Gratings

Riveted Gratings

Heavy Duty Gratings

Stainless Steel Gratings

Aluminum Gratings

Welded Gratings

Stair Treads

Ditch Inlet & Airport Grates

ALGRIP ® Surface

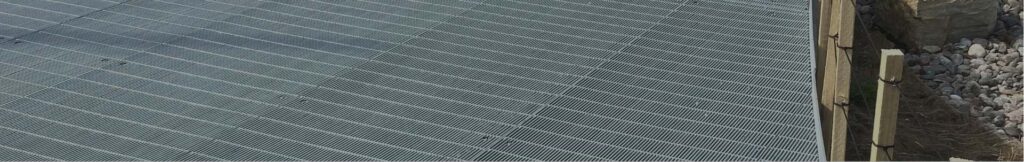

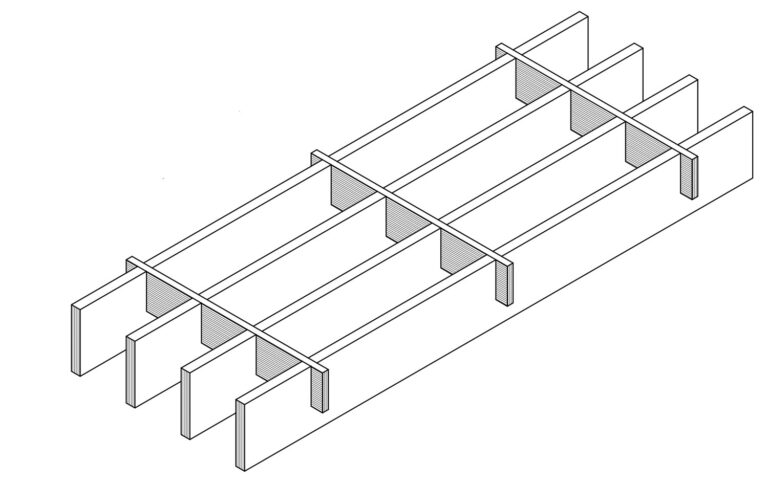

Roadway Gratings

Borden’s roadway gratings are trusted and installed across North America, especially on Bascule (lift) bridges where strength and airflow are critical. These gratings are designed with an open pattern that allows up to 80% free air passage, offering a strong yet lightweight solution.

Product Options and Benefits

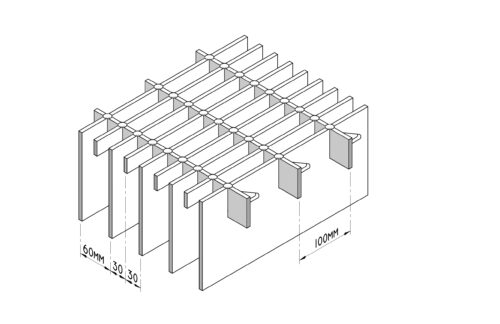

Rectangular Roadway Gratings

A cost-effective option, offering the highest level of open area for air and water flow.

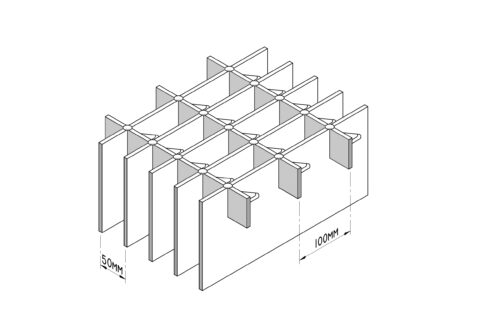

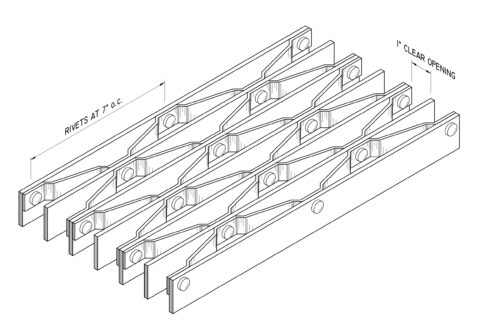

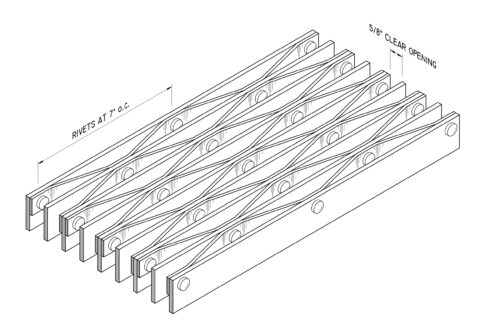

Riveted Roadway Gratings

A cost-effective option, designed for added lateral support, these gratings use a crimped design that acts like a truss. The crimp can be slightly raised to ensure a smoother, more comfortable ride.

I-Bar Roadway Gratings

These provide the best strength-to-weight ratio among all Borden products. Available in several styles:

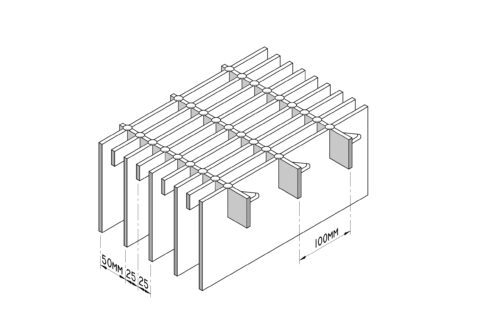

– Standard Rectangular

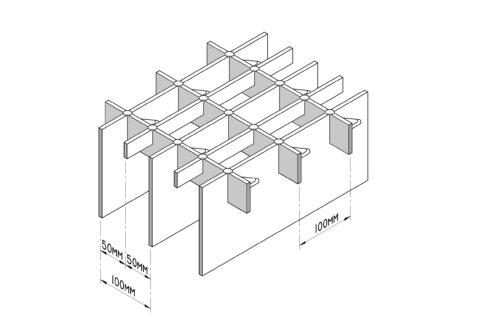

– R/W-I (with truss-like crimp)

– Concrete-filled for added durability

Engineering Considerations

Design tables are available to help engineers meet strength and deflection requirements. Fatigue performance should be evaluated based on the specific needs of each project.

Rectangular Roadway

Riveted Gratings

Rectangular Roadway

Image

Product

Documents

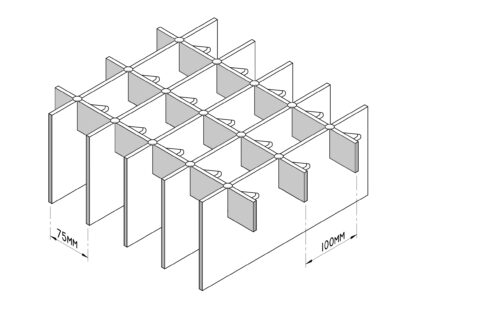

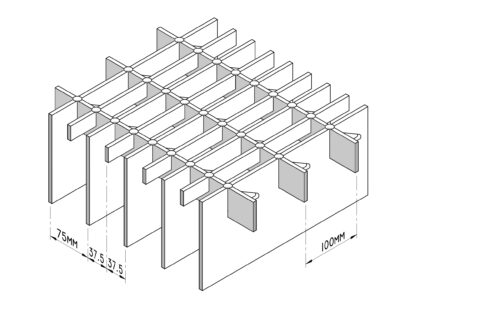

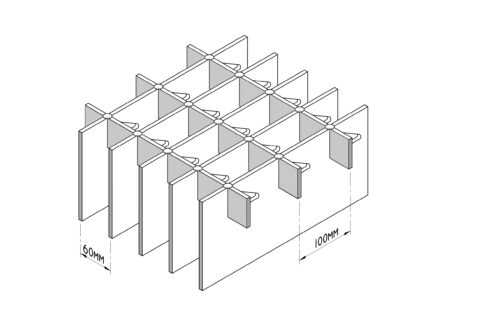

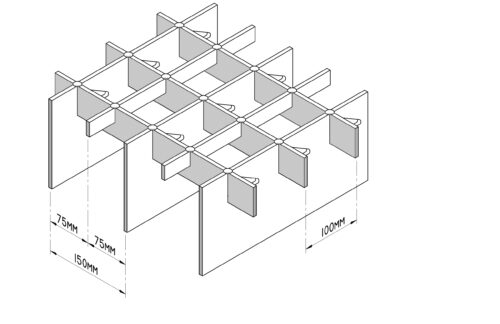

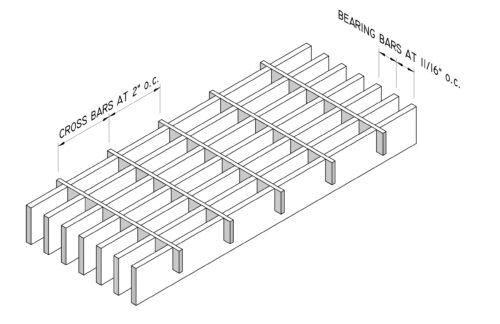

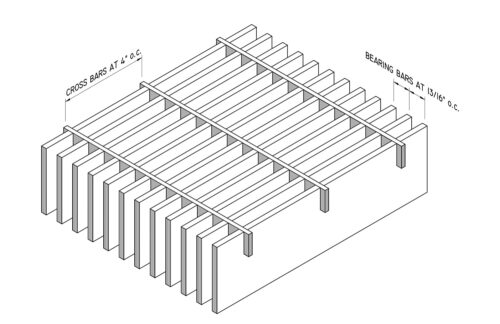

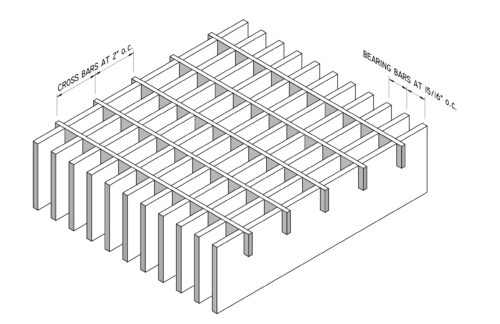

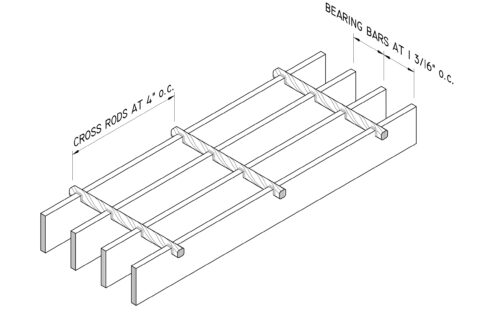

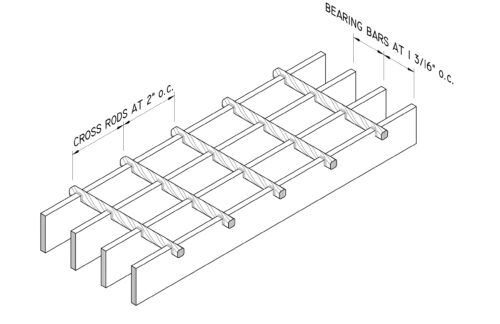

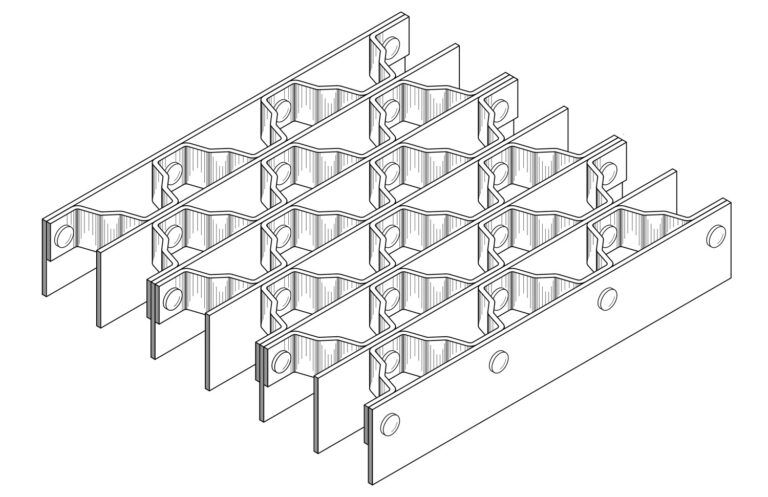

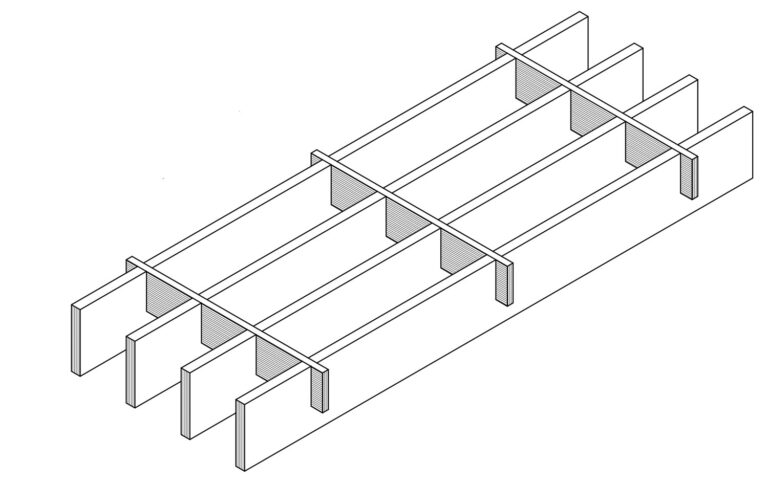

Pressure Locked Gratings

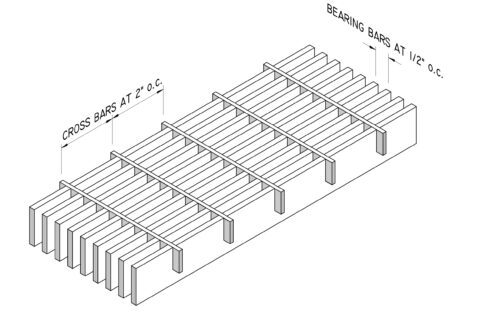

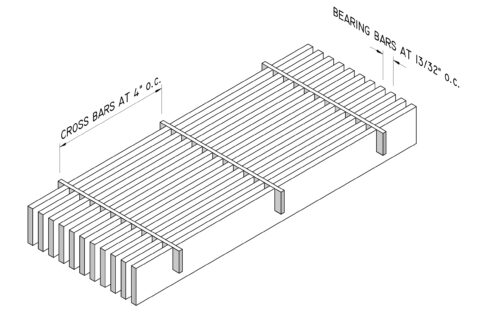

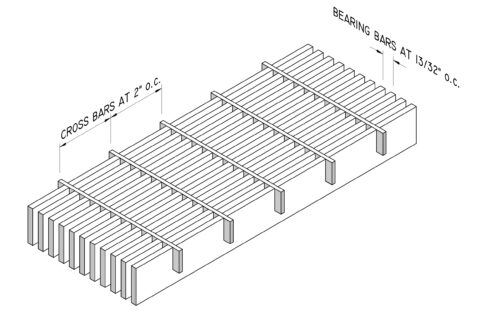

Pressure Locked Grating is a preferred choice for many applications due to its clean, modern appearance, smooth lines, and exceptional durability. It also provides outstanding lateral support.

This type of grating is manufactured by hydraulically pressing two precisely slotted bars together, creating a permanent mechanical lock. This method allows for greater design flexibility than any other grating type.

Key Features

- Customizable Design: Bar sizes and spacing can be tailored to specific needs, with center-to-center spacing starting as small as 13/32″ (providing a 7/32″ clear opening).

- Material Options: Available in aluminum, carbon steel, galvanized steel, and stainless steel, making it suitable for a wide range of environments and applications.

Image

Product

Documents

Borden Type C

(11-P-4)

Borden Type CF

(11-P-2)

Borden Type BB

(9.5-P-4)

Borden Type BBF

(9.5-P-2)

Borden Type LL

(8-P-4)

Borden Type LLF

(8-P-2)

Borden Type DD

(6.5-P-4)

Borden Type DDF

(6.5-P-2)

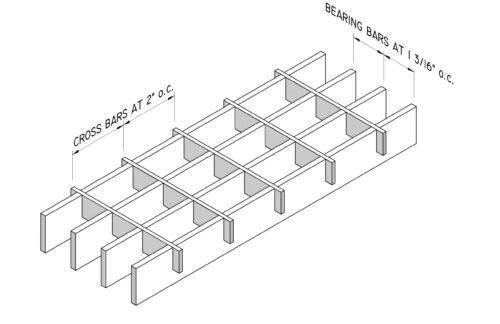

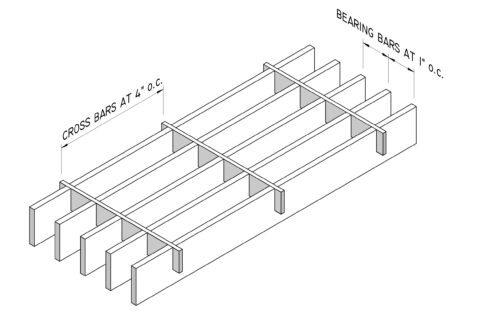

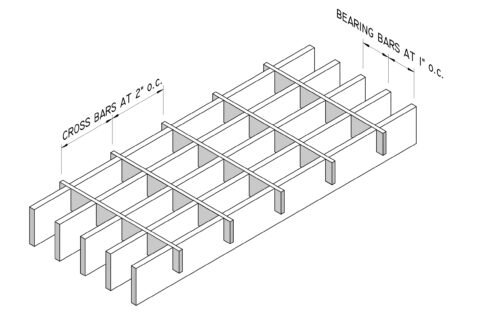

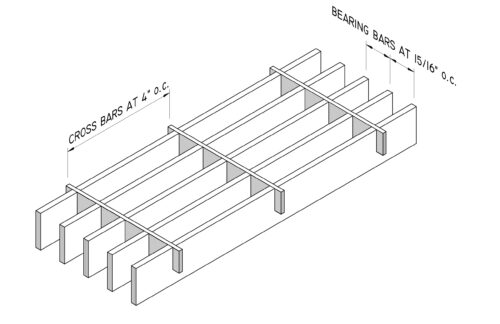

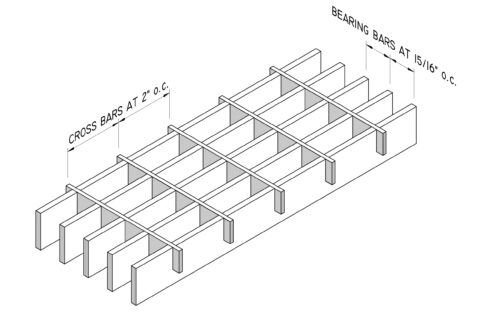

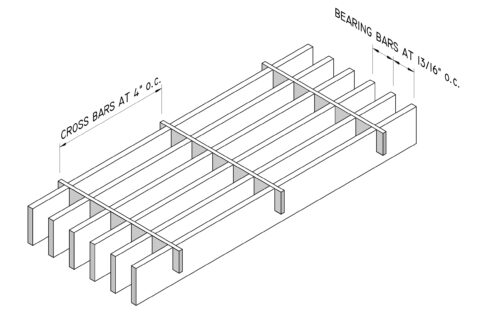

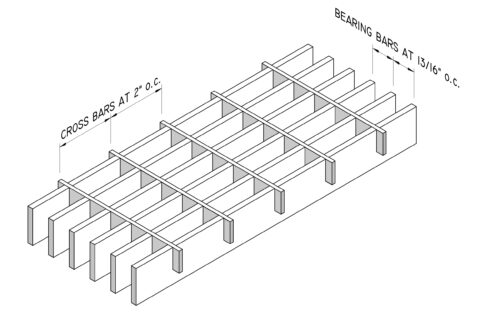

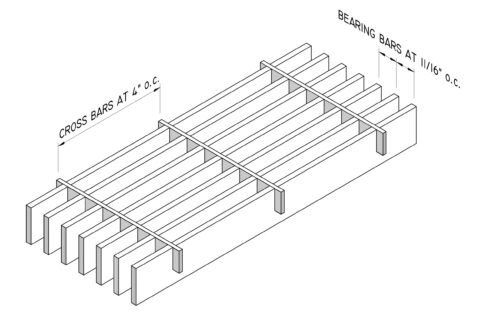

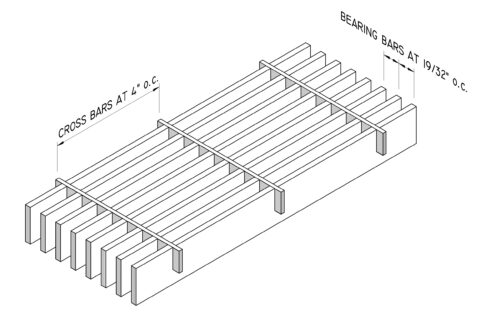

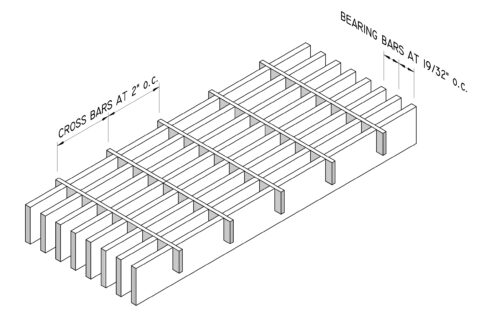

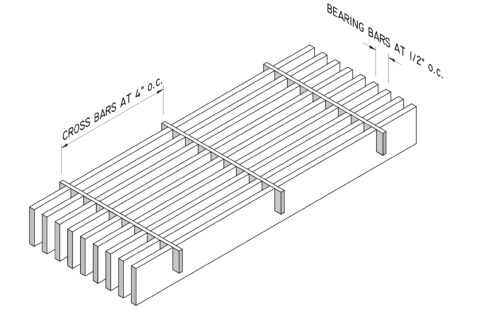

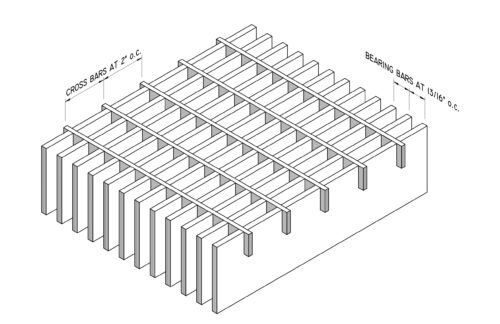

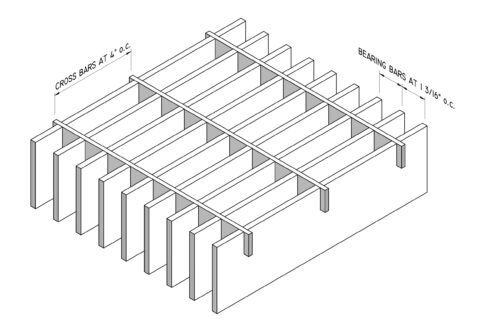

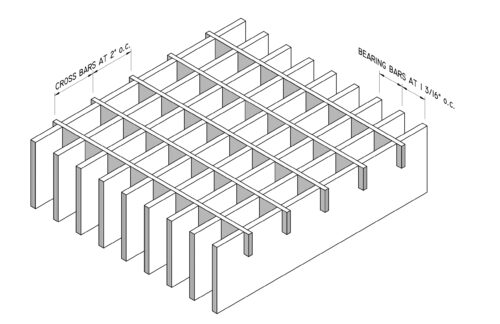

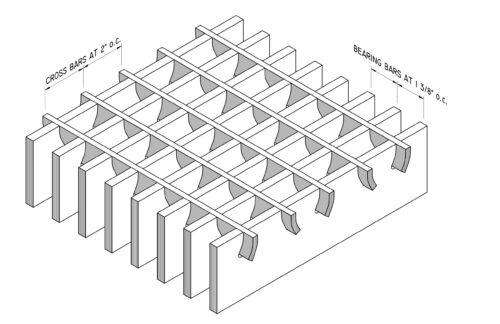

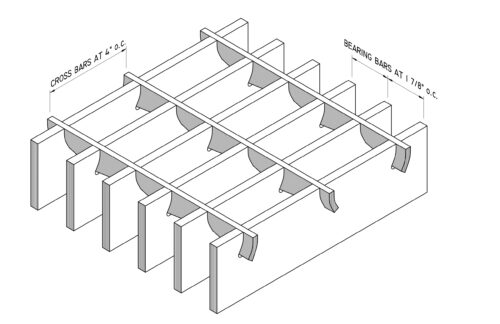

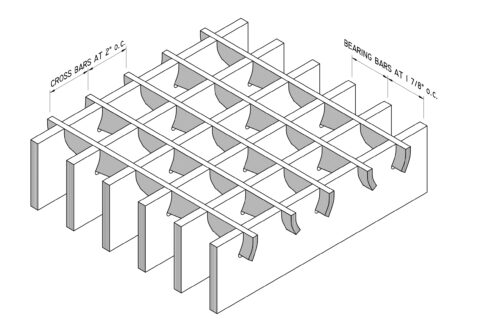

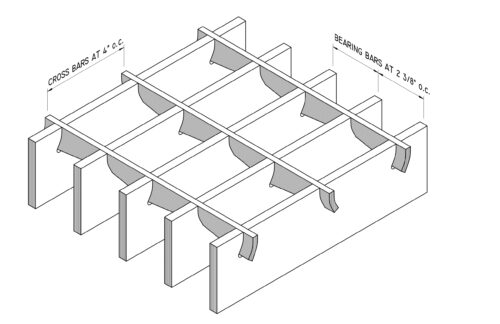

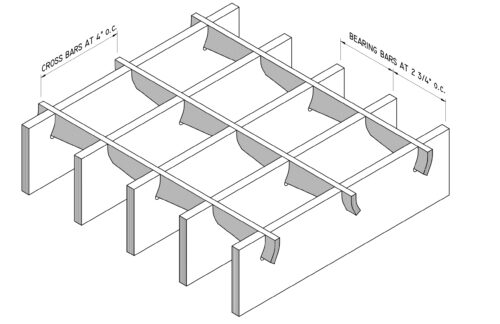

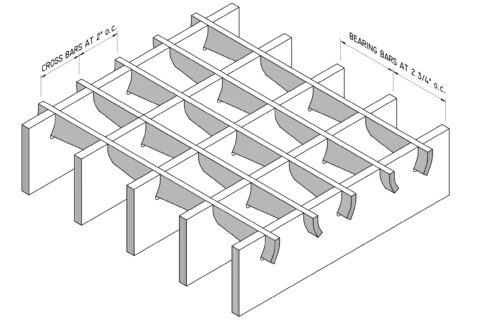

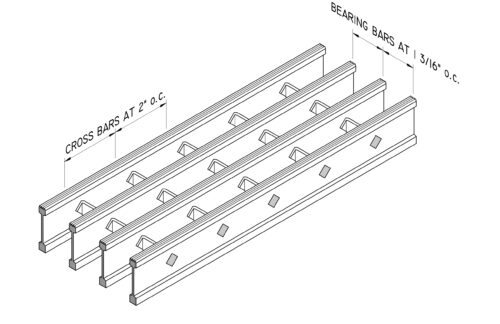

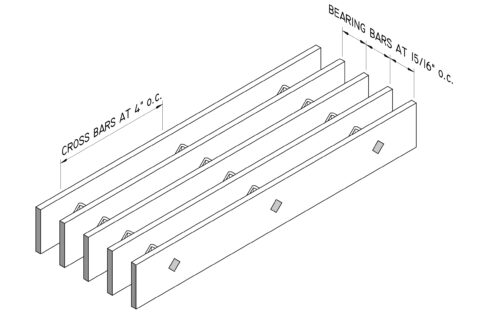

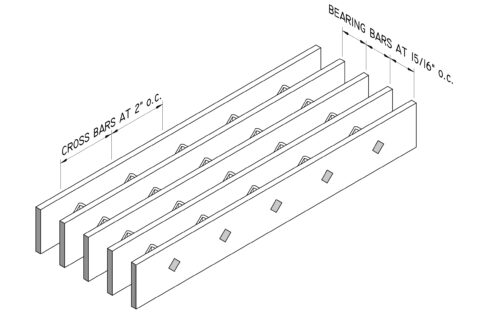

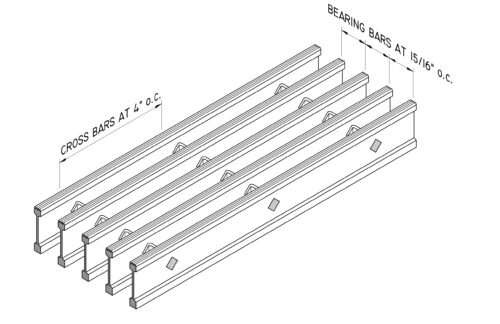

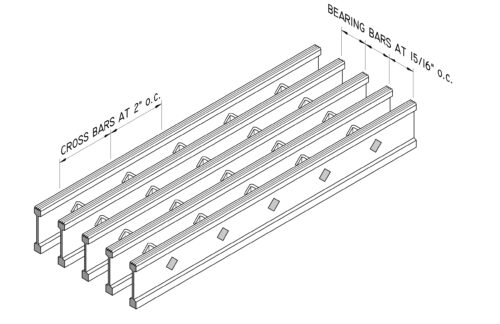

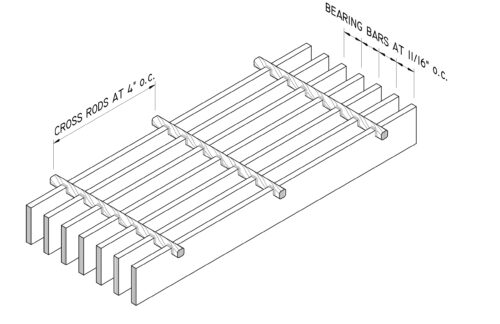

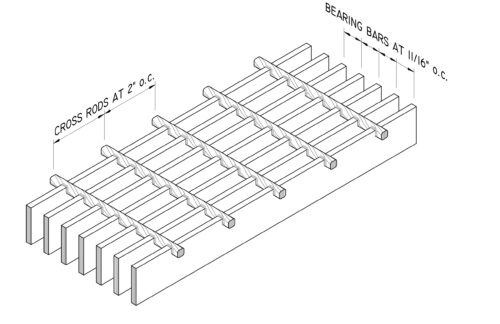

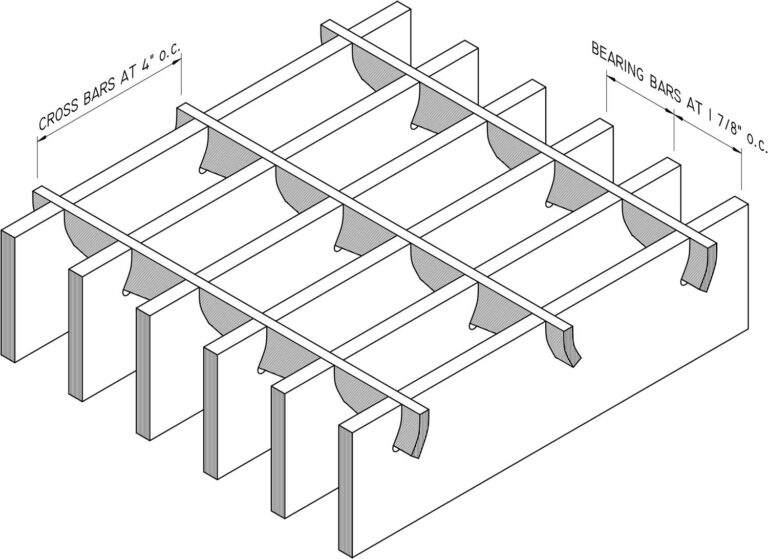

Sidewalk Gratings

Borden Sidewalk Grating is engineered to provide both pedestrian comfort and structural strength, making it ideal for sidewalks, plazas, and other pedestrian-accessible areas. Its design features small openings that enhance safety by reducing the risk of tripping or heel entrapment, while maintaining the capacity to support occasional vehicular loads. The grating is available in a variety of bearing bar and cross bar spacing configurations to meet specific free air and drainage requirements. For enhanced slip resistance, customers can choose between a premium ALGRIP® surface or a mechanically punched serrated finish, both of which improve traction.

Borden Sidewalk Grating complies to the design requirements of ANSI/NAAMM MBG 534-24 standards, ensuring reliable performance and safety. However, it is essential to consult local municipal codes to confirm the appropriate product selection for specific applications.

Image

Product

Documents

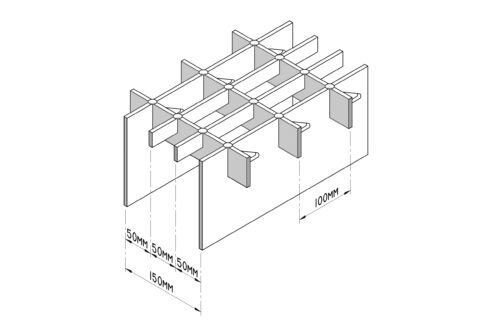

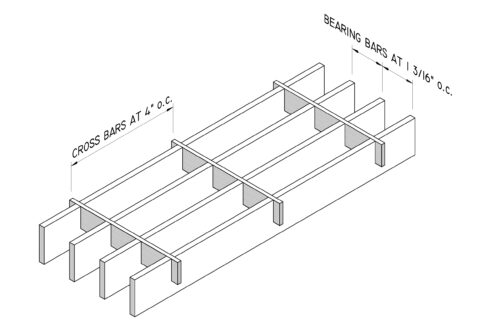

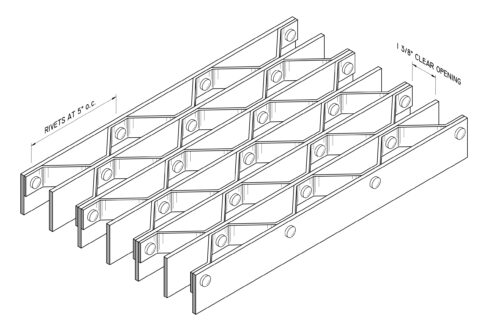

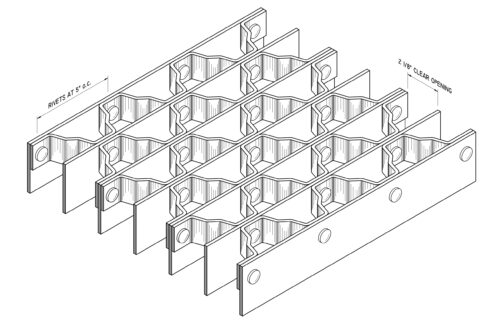

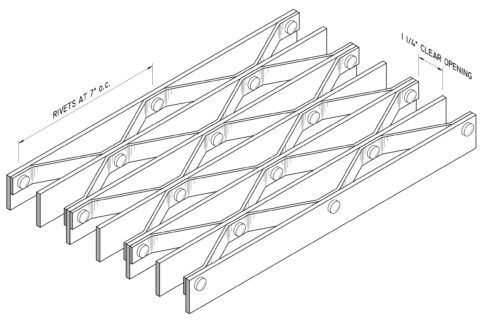

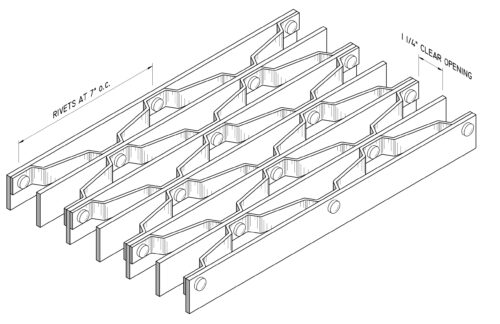

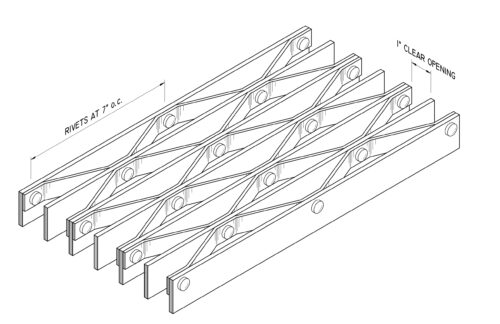

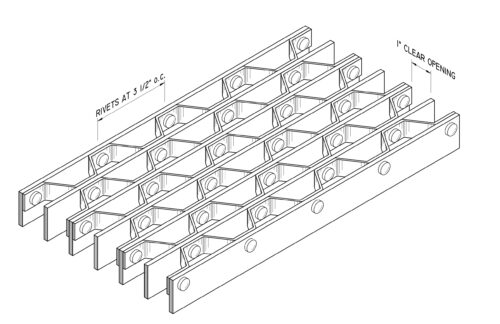

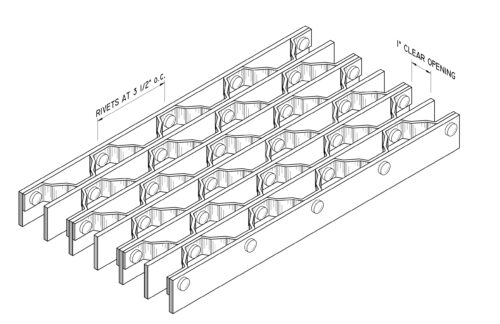

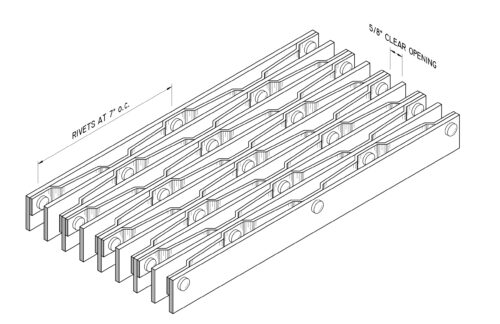

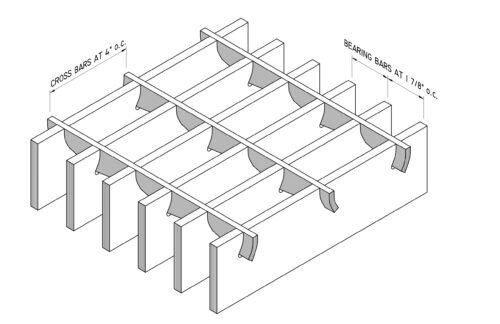

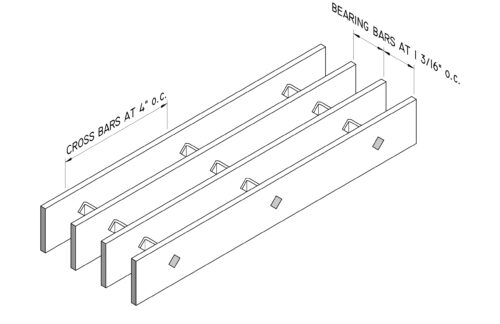

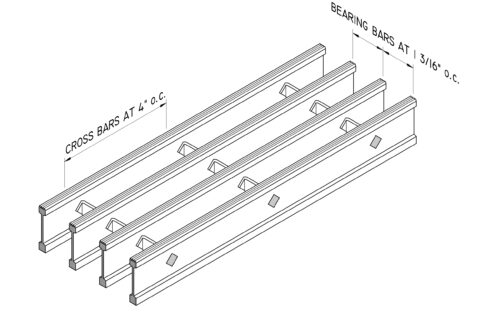

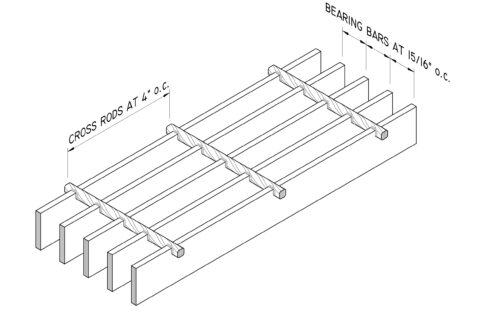

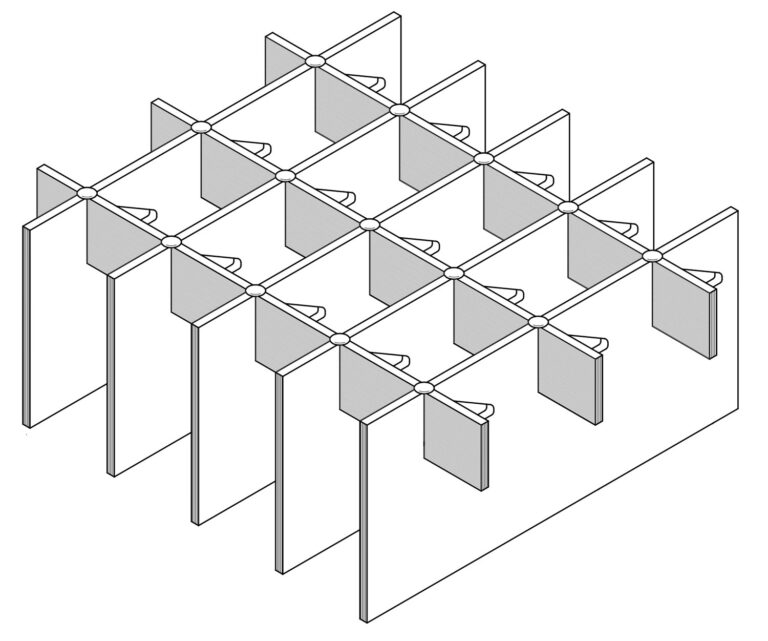

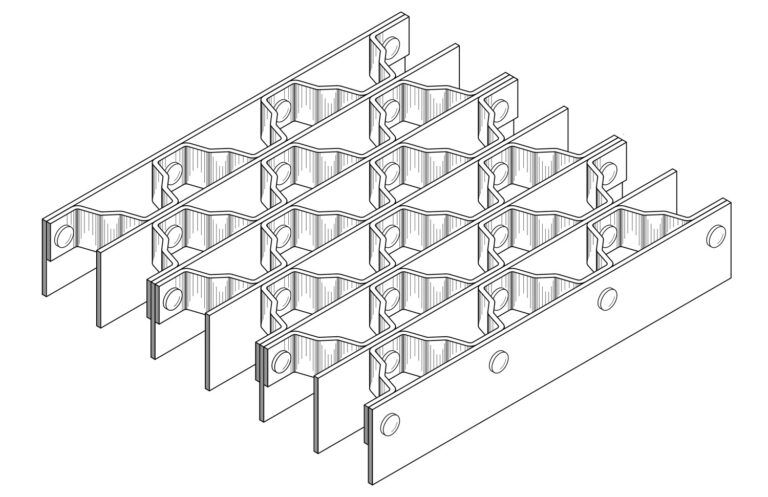

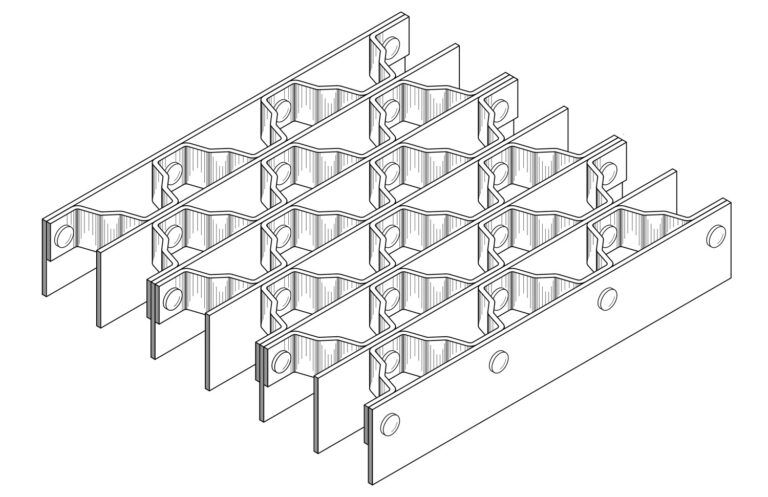

Riveted Gratings

Riveted grating represents the earliest and most structurally robust form of industrial grating still in production. Engineered on the truss principle, this design ensures superior lateral load distribution, torsional rigidity, and impact resistance, making it ideal for high-load and dynamic environments.

Borden Riveted Gratings are precision-fabricated to deliver optimal performance in demanding industrial applications. The riveted construction method mechanically fastens bearing bars and crimp bars, forming a unified load-bearing structure that minimizes deflection and enhances fatigue life under cyclic loading.

These gratings are particularly suited for:

– Vehicular traffic (e.g., forklifts, highway trucks)

– Heavy-duty industrial flooring

– Bridge decking and infrastructure

– Dynamic load zones in manufacturing and logistics

A key engineering advantage is the use of serrated and raised crimp bars, which provide enhanced slip resistance without necessitating increased bearing bar depth—thereby maintaining structural efficiency and minimizing weight.

Material Options:

– Carbon Steel: High strength and cost-effective for general industrial use.

– Stainless Steel: Corrosion-resistant for chemical, food processing, and marine environments.

– Aluminum: Lightweight and corrosion-resistant, ideal for weight-sensitive applications.

Riveted grating is specified where load uniformity, long-term durability, and operator safety are critical. For detailed load tables and deflection data, refer to the accompanying technical documentation.

Image

Product

Documents

BORDEN TYPE G

(25-R-5)

BORDEN TYPE RW

(37-R-5)

BORDEN TYPE A

(18-R-7)

BORDEN TYPE K

(18-R-7)

BORDEN TYPE E

(18-R-3.5)

BORDEN TYPE U

(18-R-3.5)

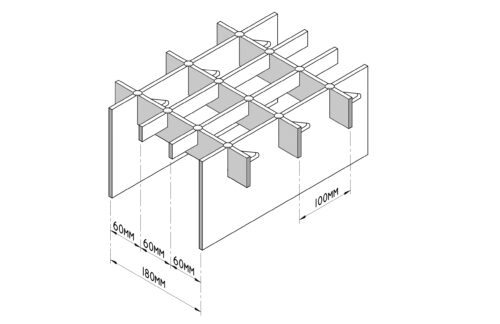

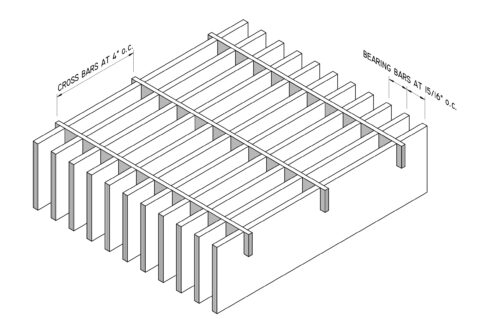

Heavy Duty Gratings

Heavy-Duty Bar Gratings are specifically engineered to withstand high-impact, concentrated loads typically imposed by industrial vehicular traffic, including forklift trucks and highway-rated vehicles. These gratings are fabricated to meet stringent structural performance requirements in environments where durability and load-bearing capacity are critical.

Heavy-Duty Bar Gratings are specifically engineered to withstand high-impact, concentrated loads typically imposed by industrial vehicular traffic, including forklift trucks and highway-rated vehicles. These gratings are fabricated to meet stringent structural performance requirements in environments where durability and load-bearing capacity are critical.

Typical applications include:

- Linear drainage systems and trench grates

- Sump and vault access covers

- Industrial mezzanine and floor systems

- Airfield drainage infrastructure

- Highway and transportation catch basins

Design parameters conform to the structural strength and deflection limits prescribed in ANSI/NAAMM MBG 534-24. Consideration of fatigue performance under cyclic loading conditions is recommended and should be evaluated by the responsible structural or civil engineer based on project-specific service conditions.

Image

Product

Documents

Stainless Steel Gratings

Borden offers a versatile range of stainless steel and specialty alloy gratings, engineered for environments where heat and corrosion resistance are critical. Our gratings are available in multiple configurations to meet your specific needs, including:

- Pressure-Locked Style

- Heavy-Duty Style

- Riveted Style

Built for durability and performance, Borden gratings deliver reliable solutions for demanding industrial applications.

Pressure Locked Gratings

Heavy Duty Gratings

Riveted Gratings

Squeeze-Locked Grating

Image

Product

Documents

Aluminum Gratings

Aluminum offers exceptional material properties, including a high strength-to-weight ratio, spark resistance, and excellent corrosion resistance. These characteristics make aluminum grating an ideal choice for a wide range of applications, including water and sewage treatment plants, marine environments, and refineries.

Aluminum offers exceptional material properties, including a high strength-to-weight ratio, spark resistance, and excellent corrosion resistance. These characteristics make aluminum grating an ideal choice for a wide range of applications, including water and sewage treatment plants, marine environments, and refineries.

Aluminum gratings are available in several types:

- Pressure-locked

- Swage-locked (squeeze-locked)

- Riveted

- Heavy-duty (consult our Engineering Department for loading specifications)

In terms of cost, aluminum gratings generally range from least to most expensive as follows: swage-locked, pressure-locked, and riveted. For additional weight and cost savings, an I-bar section may be used instead of a flat bar in swage-locked grating.

For detailed loading information, please click the buttons below or contact our Engineering Department.

Squeeze-Locked Grating

Pressure Locked Gratings

Riveted Gratings

Welded Gratings

Image

Product

Documents

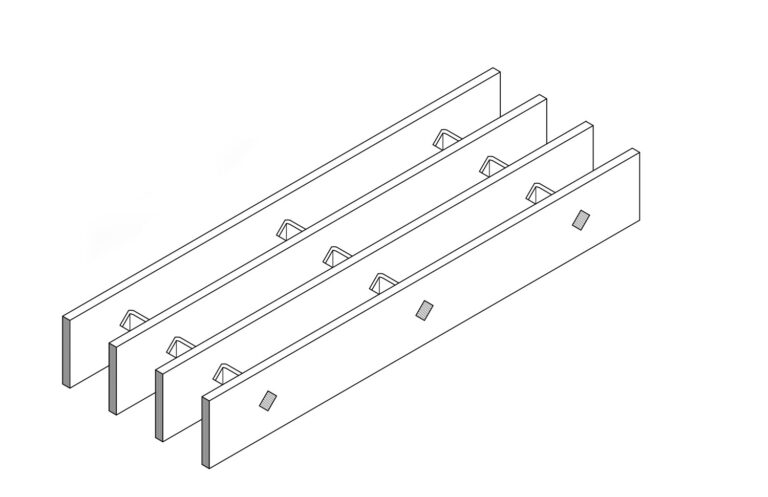

Stair Treads

Borden Stair Treads are engineered for durability, safety, and versatility. Available in Carbon Steel, Aluminum, and Stainless Steel, these treads are custom-fabricated to fit any stair or tread opening. Each unit is delivered with pre-punched and slotted end plates, ready for bolting to stringers.

Borden Stair Treads are engineered for durability, safety, and versatility. Available in Carbon Steel, Aluminum, and Stainless Steel, these treads are custom-fabricated to fit any stair or tread opening. Each unit is delivered with pre-punched and slotted end plates, ready for bolting to stringers.

Material Options and Specifications

Carbon Steel Treads

Grating Types:

- Pressure Locked

- Welded

- Riveted

Aluminum Treads

Grating Types:

- Pressure Locked

- Squeeze Locked (Standard Bar or I-Bar)

- Riveted

Stainless Steel Treads

Grating Types:

- Pressure Locked

Nosing Material

Refer to the document below for information on nosing types for each product.

| Nosing Types |

Mounting Information

Treads are supplied with pre-punched and slotted end plates for easy installation.

Mounting bolts (3/8″ or 10 mm) are not included and must be supplied by the installer.

| End Plates Details |

Design Reference

Refer to the accompanying tables for maximum recommended tread lengths based on material and grating type.

| Steel Treads |

| Aluminum Treads |

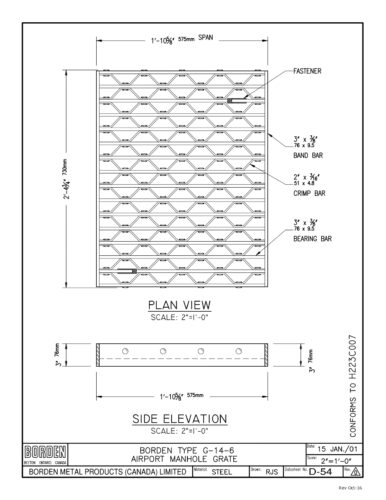

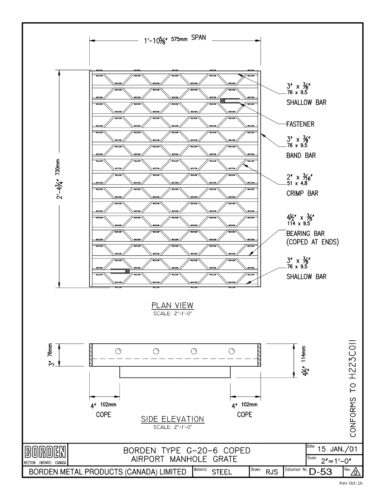

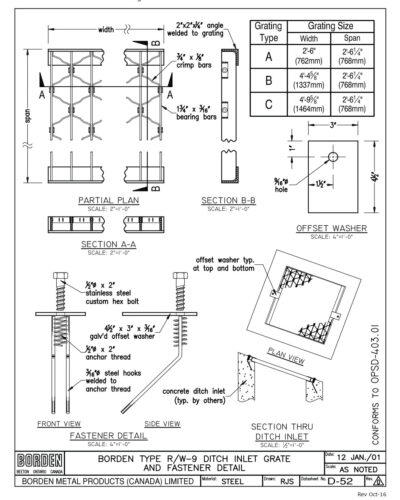

Ditch Inlet & Airport Grates

Borden Metal Products (Canada) Limited produces all types of Airport and Ditch Inlet Grates conforming to Federal, State, and Provincial requirements. Transport Canada drawings H223C007 and H223C011, and Ontario Provincial Standard Drawing OPSD-403.01 are kept on stock in our yard.

To review these drawings, click the images below: